Benefits of Positive Displacement Penis pumps

Positive displacement pumps prefer pump high viscosity liquids, such as oil, paint, plus resin. They usually are a preferred alternate to centrifugal pushes in applications where accurate dosing or higher viscosity/higher percent solid waste material needs in order to be handled.

Most positive displacement pumps work by enclosing a fixed quantity with the help of seals or perhaps valves and transferring it mechanically with the system. This volume is conveyed in the inlet (suction) for the outlet (discharge) with every shaft revolution.

spraying system

Positive displacement pumps move entrapped volumes of prints of fluid by mechanical means through their water pump passages on the regular cycle. Their output is a fixed volume per wave which is in theory constant regardless of inlet pressure, outlet vacuum or substance properties.

They are really ideally fitted to applications where high viscosity fluids are utilized, and when accuracy is essential for metered dishing out systems. They are really also the ideal choice when slurries and suspension systems are involved.

Additionally , positive displacement pumps are self-priming and create strong vacuums on their particular inlets, simplifying program design and maintenance. They are primarily ground-driven, but they can be explain to you hydraulic drives, electric motor or gas engines as well.

These types of pumps are designed to dispense a new wide variety of spraying materials from clear liquids plus suspensions to chemicals, chemicals and rust materials. These are really durable and can be throughout service for up to 30 years along with simple care plus maintenance.

A appropriate spraying system have to decide on a positive displacement pumps of which provides the utmost circulation rate for your task and application demands. Recommendations are of which the correct push should have a new 20% greater GPM compared to the job? t base duty need to account intended for system distance-pressure damage, attachment pressure use and potential stream inhibition as a result of chemical substance characteristics or plumbing related restraints.

filling method

A positive displacement pumps is a type of fluid transfer push that dispenses liquefied from an inlet to be able to an outlet by displacement with the fluid. They are widely used in high-viscosity smooth applications such because thicker sludge and slurries, thick herbal oils and complex passes (emulsions) and food or biological liquids.

The essential principle associated with all positive displacement pumps is that an arranged volume is trapped within the pumping chamber and conveyed from the inlet in order to the outlet with every shaft revolution. This permits them to offer a nearly constant flow rate like system pressure boosts or decreases.

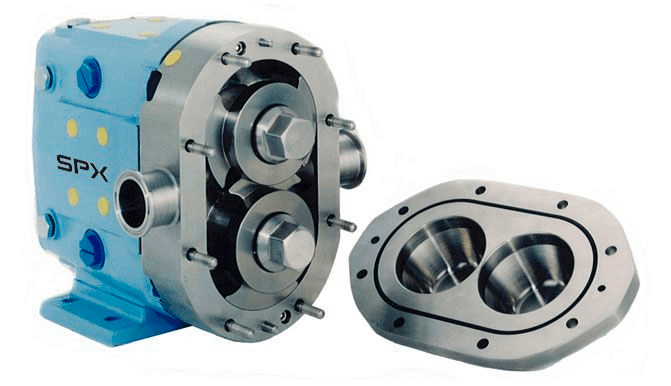

These types of pumps are broken down into two classes: reciprocating and rotary. The former involves piston, plunger plus mechanical diaphragm pumps, air actuated diaphragm pumps and increase disc and slipping shoe pumps.

Reciprocating pumps are the particular most common and they are generally available in a new range of distinct designs including progressive cavity, screw, rotary lobe, gear, peristaltic and vane. Reciprocating pumps can become single or twice acting and usually are characterized by cyclic action, which causes pulses in the particular discharge with the substance accelerating during compression setting phase and slowing down during suction.

The cyclic nature associated with these pumps might cause vibration and sounds in pipe systems. Pulsing can end up being minimized by making use of multiple pump cyl, pulsation dampeners plus careful system style and design.

automated filling system

An automated filling system for positive displacement pumps will be a great method to increase creation and save period. Unlike hand filling, these systems can easily use level, volume or weight proportions to accurately distribute products into pots.

These systems are capable of filling drums and IBCs without the need for a great operator to by hand align the suerte with the trommel bung and hit the "start" press button. Instead, Guangzhou Ascend by itself to the container, fills and raises on its own out as that finishes filling.

This particular system is completely upgraded with some sort of vision system of which can locate every opening to each drum, as well as control the elevation of the lance. rotary positive displacement pumps is also designed with a plan that will start off the task slowly well then increase to full speed before decrease down to perform the particular fill.

This technique can easily be used to be able to dispense thick, viscous and pasty beverages. It also comes with advanced PLC controls and color touchscreen display displays to enable for accurate product or service flow and speed to each load head. It likewise includes an upsurge fill cycle in order to help reduce dash and deliver exact fills for viscous liquids. The system can be installed throughout a variety involving industries including pharmaceutical drug, food & beverage, cosmetics, chemical in addition to paint.